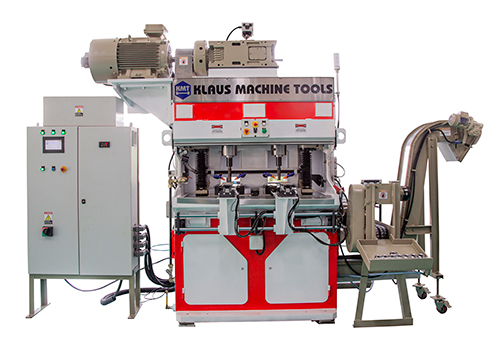

Twin Spindle Tapping Machine

Information About Tapping Process

Description: This is a Precision thread cutting machine, cutting threads by means of high precision carbide tap. In this machine, as a rule, the pitch of the thread is set up by means of change gears in conjunction with a lead screw and nut. The gears of the feed train are manufactured to a high degree of precision and the feed is derived through high precision ball screw.

Advantages of Heavy-Duty Tapping Machine:

- The machine offers high production rate hence, the cost per component can be very low.

- The machine is designed in a such way that it can achieve max torque at low rpm for tapping of M80X6 mm pitch and for M27X3 mm pitch. Thereby the machine provides torque at high rpm through reduced gear box and electric motor.

- The machine is suitable for tapping up to M80X6 mm pitch in single pass which is not possible with an ordinary tapping machine.

- The automatic material feeding unit and automatic material unloading unit makes the machine completely automated tapping machine.

- The variable frequency drive unit of the machine (100) offers various cutting speeds for speed of operation.

Salient Features of this Machine:

Lead control mechanism which provides precise positive axial movement of the tap into the predrilled hole corresponding to the lead of the thread tap

(A) Automatic reversal of spindle at the end of tapping

(B) Safety arrangement to prevent tap damage due to overload.

Appropriate cutting speeds of tapping are established based on the material of job to be cut, material of the tap and cutting oil/ tool lubrication provision.

Refer General Assembly drawing of the machine ( Drg. Attached)

The machine is designed and built for tapping operation ranging from dia. 27 mm x 3 mm pitch to dia. 80 mm x 6 mm pitch. Being two station machine, two spindles carry out thread cutting of two jobs simultaneously.

Klaus Machine Tools (KMT) is a group company of Randack Fasteners India located in Pune having vast experience in Manufacturing of High Tensile Fasteners, Precision Machined component. KMT now entering in new business of Design and Manufacturing of Tapping machines and establishing as OEM in this sector.

Tapping Machine can reduce the efforts of operator with high productivity.

To make the most of its outstanding performance for long period, this machine must be properly installing and operating and maintenance procedure must be clearly understood and carefully followed. You are encouraged to study this instruction manual carefully before the machine installed and to keep on file for further reference.

Background of The Tapping machine

A traditional screw threading process includes fixing a work piece into a fixture and starts tapping with a knife. The method can work on a single piece at a time, and tapping procedures starts after waiting for a hole to be drilled thereon. This reduces speed of operation and efficiency of the process. In addition to this, in manual operation, chances of breaking of the thread is high, and makes this higher cost of production. Therefore, it is necessary to adopt automation in the field of tapping that would increase the accuracy, operating efficiency of the technicians, and reduced processing cost.

Information About Tapping Process

Description: -

This is a Precision thread cutting machine, cutting threads by means of high precision carbide tap. In this machine, as a rule, the pitch of the thread is set up by means of change gears in conjunction with a lead screw and nut. The gears of the feed train are manufactured to a high degree of precision and the feed is derived through high precision ball screw.

Advantages of Heavy-Duty Tapping Machine:

1. The machine offers high production rate hence, the cost per component can be very low.

2. The machine is designed in a such way that it can achieve max torque at low rpm for tapping of M80X6 mm pitch and for M27X3 mm pitch. Thereby the machine provides torque at high rpm through reduced gear box and electric motor.

3. The machine is suitable for tapping up to M80X6 mm pitch in single pass which is not possible with an ordinary tapping machine.

4. The automatic material feeding unit and automatic material unloading unit makes the machine completely automated tapping machine.

5. The variable frequency drive unit of the machine (100) offers various cutting speeds for speed of operation.