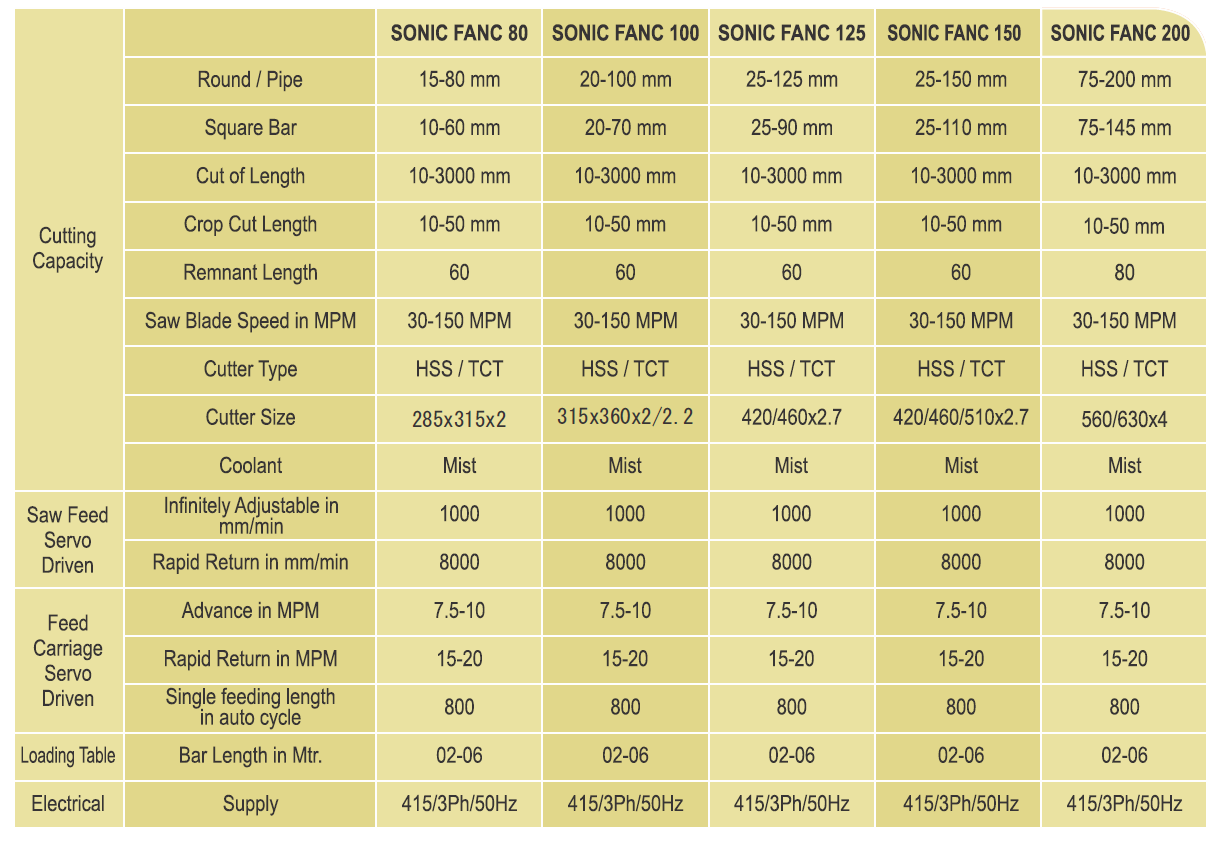

Circular Saw Machines Sonic Fanc Series

FEATURES

- Suitable for processing of a large number of materials and shapes: solid material, tubes, square, Rectangle material and profiles.

- Torsion free construction, Heave duty Fabricated Structure of Machine.

- Infinitely variable controlled Cutting feed through Ball Screw Servo motor arrangement.

- Variable Frequency Drive (Inventor) for various cutting speed.

- Precise Indexing of job through Ball Screw Servo motor arrangement with+/-0.050* mm Accuracy

- Cut of length measured by PLC Using Servo Drive arrangement.

- Multiple Shuttle index stroke for cutting length up to 3000mm.

- PLC Control system with Touch Screen HMI allows easy operation without the need for machining of programming knowledge.

- HMI with self diagnostic feature for easy trouble shooting, warning, alerts, etc.

- Auto and manual mode for cycle sequence.

- Hydraulic Operated job clamping horizontal and vertical Vice.

- Heavy duty reduction Gearbox for heavy cutting torque mounted on Linear Motion Guide ways for vibration free cutting to optimize cutter life and production.

- Inbuilt micro mist cooling arrangement.

- Separate Hydraulic Power pack with all control valves, gauges & Oill level indicator for easy check & maintenance.

- Electrical Control Panel with high quality switch gears

- The robust inclined guide of the saw head ensures a perfect rake angle and guarantees high cutting accuracy with maximum performance.

- Driver brushes for cleaning of chips from circular blades

- To reduce saw blade vibration, the machine is equipped with special saw blade plate guides that move the blade near to the teeth on both sides, This enables maximum cutting prceision and thge best saw blade life at low unit cost.

- Automatic Trim Cut.

- Crop Cut & End Cut Separator.

- Powered Chip conveyor.

- PLC controlled Auto Lubrication unit for periodic lubrication of all slides.